Bespoke Cable Hangers for Train Tunnel Application Date 2021 Project Name Northern Line Extension End Customer Transport for London Scope of supply Bespoke Cable Hangers Ellis Project#/Part# 1521/CH3W2-UBF-G Requirement Ellis were approached by a customer to supply cable hangers for a rail project. Cable hangers are standard products for Ellis and we carry a wide range in stock. We can also offer bespoke solutions which are designed and fabricated entirely in the UK. On this occasion the requirement was a little different, the hangers were required to be affixed to a tunnel lining in a rail tunnel using a non-standard mounting. Usually, the team at Ellis would travel to site to size up the fitment details and ensure that they had fully understood the requirement, this would include hanger loadings, location, installation considerations etc. Due to restrictions in place because of Covid, this was not possible. The customer took photographs and provided measurements. Ellis then developed a product around this specification with consideration taken into account for the “unknown unknowns” to ensure a perfect fit on site and a product that was fit for purpose. FEA was used to check the strength of the hangers prior to production drawings being released.

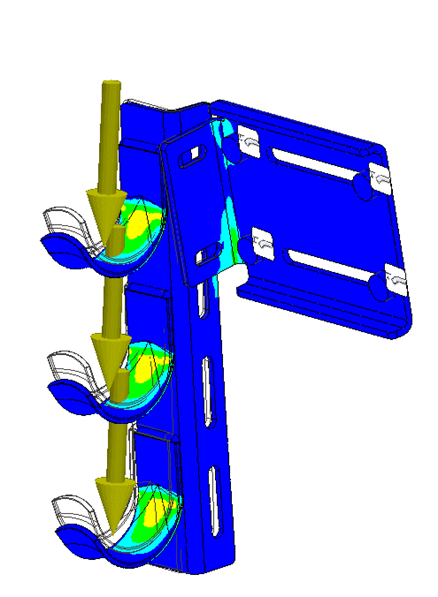

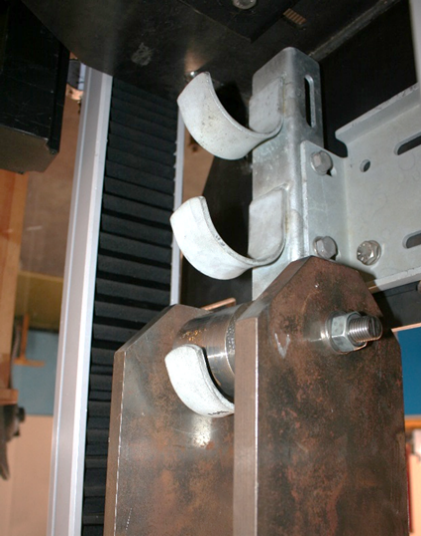

Solution Ellis used their 3D CAD design capability to create a design. The strength of the product was then checked with FEA and hand calculations. Once this was complete manufacturing drawings were released to the production team at Ellis who then used their plasma cutter to create prototypes on a very short timescale. These were tested at Ellis on site test facility to validate the strength and the prototypes were supplied to the customer for a trial fitment. This went well and Ellis proceeded to manufacture the full quantity of hangers.

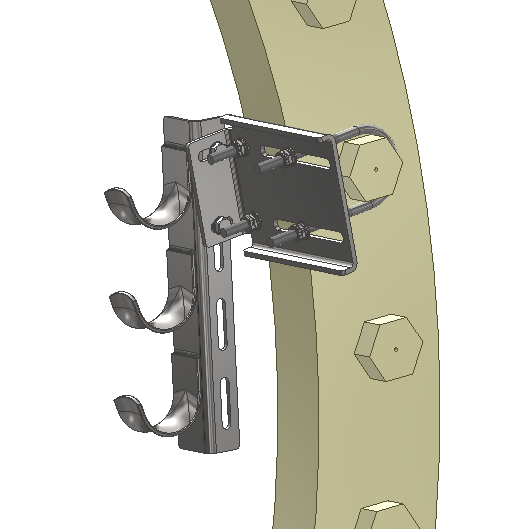

Completed hanger assembly complete with mounting fixings

3D CAD software used to design hanger and create virtual installation location

FEA (Finite Element Analysis) of design with loads applied

Hanger being load tested in Ellis test facility